Hexagon Bolts and nuts are among the most commonly used fastening systems in mechanical, construction, automotive, and industrial applications. They are designed to provide secure and reliable connections for a wide range of heavy-duty and high-performance needs. As integral components in fastening, these Bolts and nuts are essential for ensuring the stability and durability of structures, machinery, and equipment.

The hexagonal shape of the bolt head and the corresponding nut provides several key advantages over other types of fasteners. This design offers more surface contact area, making it easier to apply torque and achieve a stronger, more secure hold. Hexagon Bolts and Nuts are available in various sizes, materials, and finishes, making them suitable for diverse applications across different industries.

In this detailed guide, we will explore everything you need to know about hexagon bolts and nuts, including their construction, materials, types, applications, and installation processes. This guide is intended to help you choose the right hexagon bolts and nuts for your specific project needs.

High Strength and Durability

Hexagon bolts and nuts are specifically designed for heavy-duty applications, offering superior strength and durability. They can withstand significant loads, stresses, and forces, making them ideal for securing machinery, structural elements, and heavy equipment. Their robust design makes them suitable for use in high-torque situations where standard fasteners might fail.

Ease of Installation and Use

Hexagon bolts are designed with a hexagonal-shaped head, which allows for easy handling and installation. The flat sides of the head provide a large surface area for wrenches or tools to grip, making them easy to tighten or loosen. This user-friendly design makes them ideal for applications where frequent adjustments, removals, or maintenance are required.

Versatility Across Applications

Due to their robust design, hexagon bolts and nuts are versatile fasteners used across various industries, including automotive, construction, aerospace, and heavy machinery. They are often used to secure structural elements, attach components to equipment, and fix systems in place. This versatility makes them an essential component for a wide range of industrial and mechanical projects.

Corrosion Resistance

Many hexagon bolts and nuts are available in materials that are resistant to corrosion, such as stainless steel, galvanized steel, and coated finishes. This makes them suitable for outdoor use and in environments where they may be exposed to moisture, chemicals, or extreme temperatures. These corrosion-resistant fasteners ensure longevity and reliability in challenging conditions.

Standardized Sizing and Compatibility

Hexagon bolts and nuts come in a range of standardized sizes, which means they are easy to replace, swap, or match with other components. This standardization allows for easy compatibility with other fasteners and equipment. Whether you are working on machinery, construction projects, or assembling complex systems, hexagon bolts and nuts offer seamless integration with a variety of components.

Hexagon bolts and nuts come in several different types, each designed to suit specific applications. Below are the main types of hexagon bolts and nuts, with descriptions of their features and ideal uses.

Hexagon head bolts are the most commonly used type of bolt in industrial and mechanical applications. They feature a six-sided head, which allows for a firm grip when using a wrench or spanner. The head can be either fully threaded or partially threaded, depending on the application.

Best for: General-purpose fastening in construction, machinery, automotive, and structural applications

Advantages: Strong and reliable, easy to tighten and loosen, available in various materials and sizes

Disadvantages: Requires a wrench or spanner for installation and removal

Hexagon nuts are the matching nuts that fit onto hexagon bolts. They are used to secure the bolt in place and can be tightened to create a strong, reliable hold. Like hexagon bolts, hexagon nuts feature six sides, which provide a large surface area for easy installation and removal.

Best for: Securing bolts in place, general-purpose fastening

Advantages: Easily tightened and loosened with a wrench, available in various materials and sizes

Disadvantages: Can be difficult to remove if over-tightened or corroded

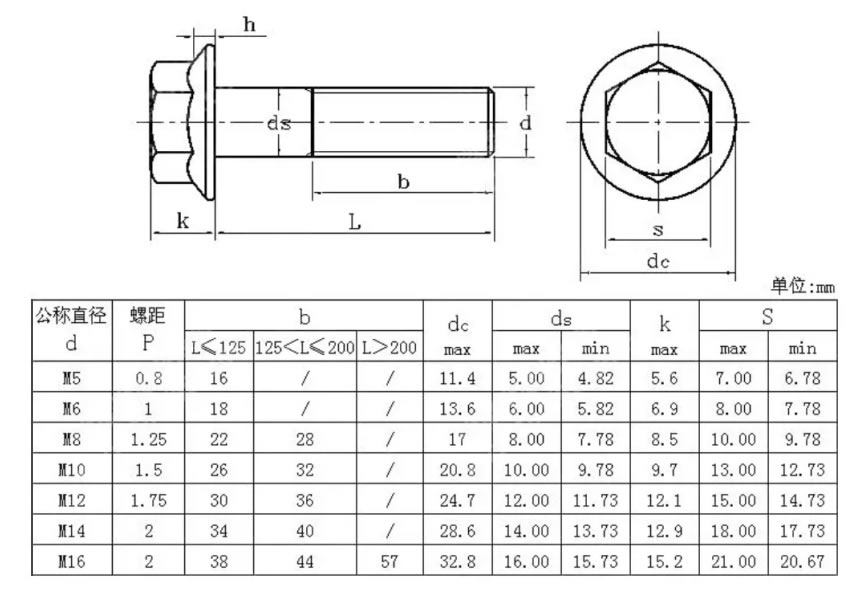

Hex Flange Bolts

Hex flange bolts are hexagon head bolts that feature a built-in flange at the base of the head. This flange acts as a washer and helps distribute the load evenly, reducing the risk of the bolt pulling out over time. Hex flange bolts are commonly used in automotive and industrial applications.

Best for: Automotive, machinery, and heavy-duty fastening

Advantages: Provides a larger surface area for load distribution, reduces the need for additional washers

Disadvantages: Can be more expensive than standard hexagon bolts

Hexagon Jam Nuts

Hexagon jam nuts are thinner nuts that are typically used in conjunction with regular hex nuts to prevent loosening. These nuts are tightened against the regular hex nut to secure the fastener in place. They are often used in high-vibration applications where standard nuts may loosen over time.

Best for: Preventing loosening in high-vibration applications, securing threaded connections

Advantages: Prevents loosening, easy to install, and cost-effective

Disadvantages: May require additional tools or components for installation

Self-Locking Hex Nuts

Self-locking hex nuts have an integrated locking mechanism that prevents them from loosening over time. These nuts are often used in environments where vibration or movement may cause traditional nuts to loosen. They are available in both nylon insert and all-metal variations.

Best for: Applications subject to vibrations, automotive, aerospace, machinery

Advantages: Prevents loosening, reduces maintenance, increases reliability

Disadvantages: More expensive than standard nuts, may require specific installation tools

Hexagon bolts and nuts are available in a variety of materials, each designed to suit specific applications and environments. Below are some common materials used in the manufacture of hexagon bolts and nuts:

Carbon Steel

Carbon steel is one of the most commonly used materials for hexagon bolts and nuts. It offers high strength, durability, and affordability. Carbon steel fasteners are ideal for general-purpose use, including in construction, automotive, and industrial applications. However, carbon steel can be prone to corrosion if not treated or coated.

Best for: General-purpose applications, low-cost fastening

Advantages: High strength, cost-effective

Disadvantages: Can rust without proper coating or treatment

Stainless Steel

Stainless steel is a corrosion-resistant material that is often used for hexagon bolts and nuts when exposure to moisture or chemicals is a concern. Stainless steel fasteners are durable and can withstand harsh environments, making them suitable for outdoor use, marine applications, and food processing industries.

Best for: Outdoor, marine, and food industry applications

Advantages: Corrosion-resistant, durable, long-lasting

Disadvantages: More expensive than carbon steel

Galvanized Steel

Galvanized steel is carbon steel that has been coated with a layer of zinc to prevent rust and corrosion. Galvanized hexagon bolts and nuts are commonly used in construction and outdoor applications where exposure to the elements is a concern.

Best for: Outdoor and construction applications

Advantages: Corrosion-resistant, affordable, widely available

Disadvantages: Coating can wear off over time in harsh conditions

Alloy Steel

Alloy steel is a high-strength material that contains other elements like chromium, molybdenum, or vanadium to enhance its properties. Hexagon bolts and nuts made from alloy steel are used in applications where higher strength, toughness, and wear resistance are required.

Best for: Heavy-duty industrial, automotive, and aerospace applications

Advantages: Extremely strong, high resistance to wear

Disadvantages: More expensive than carbon steel and stainless steel

Hexagon bolts and nuts are used in a wide range of applications across various industries. Here are some of the most common uses:

Construction and Structural Applications

In the construction industry, hexagon bolts and nuts are used to secure beams, columns, and other structural elements. They provide a reliable and strong hold for the frame of buildings, bridges, and other infrastructure projects.

Automotive and Aerospace Industries

Hexagon bolts and nuts are frequently used in the automotive and aerospace industries to assemble engines, chassis, and other critical components. Their strength and reliability make them ideal for these high-performance applications.

Heavy Machinery and Equipment Installation

Hexagon bolts and nuts are essential for securing machinery and heavy equipment. They are used to assemble large machines, secure moving parts, and ensure that equipment stays in place during operation.

Marine and Outdoor Applications

Hexagon bolts and nuts made from stainless steel or galvanized steel are ideal for use in marine environments, where corrosion resistance is crucial. These fasteners are used to secure parts

Cangzhou Yangkang is a professional supplier in the photovoltaic and infrastructure fields, focusing on the R&D and production of Ground screws (helical ground anchors), Photovoltaic (PV) Mounting Systems, Bolts, Fence caps, Wire Mesh and other products.

About

Copyright © 2022 Cangzhou Yangkang Trading Co., Ltd

SitemapMain business area: Huanghua Cangzhou CHINA

This website uses cookies to ensure you get the best experience on our website.