Wedge anchor Bolts are powerful, high-performance fasteners designed to secure heavy-duty objects to concrete, masonry, or stone surfaces. These Bolts are widely used in a variety of applications, ranging from construction and industrial projects to machinery and outdoor installations. They are specifically engineered to provide a secure, long-lasting hold, even in high-load or high-stress environments.

The wedge anchor bolt operates with a unique mechanism: as the bolt is tightened, the wedge-shaped portion of the anchor expands inside the hole, creating a firm grip on the surrounding material. This expansion mechanism ensures that the anchor remains tightly in place, making it ideal for securing heavy machinery, structural components, and other equipment that requires reliable and durable fastening.

In this comprehensive guide, we will explore the features, types, benefits, installation process, and diverse applications of wedge anchor bolts. By the end of this article, you’ll understand why wedge anchor bolts are an essential component for fastening in concrete and masonry applications, and how they can provide unmatched strength and reliability.

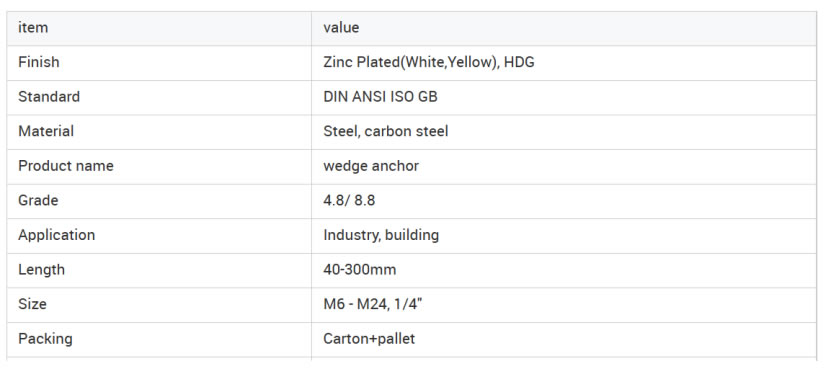

A wedge anchor bolt is a type of anchor used primarily in concrete and masonry surfaces to secure an object or structure in place. They are made of high-strength materials like steel, stainless steel, or galvanized steel, ensuring they are durable and resistant to corrosion.

Wedge anchors are designed with a wedge-shaped component that expands as the bolt is tightened. The anchor consists of three main parts:

The Bolt – The threaded shaft that holds the object or structure in place.

The Wedge – A conical, wedge-shaped element that expands when the bolt is tightened.

The Sleeve – The cylindrical housing that holds the wedge and ensures a secure grip inside the hole.

Once the bolt is inserted into a pre-drilled hole in concrete, masonry, or stone, tightening the nut forces the wedge to expand, creating a firm bond with the surrounding material. This design allows the wedge anchor to provide high load-bearing capacity and secure fastening.

High Load-Bearing Capacity

Wedge anchor bolts are designed to support heavy loads and high-stress applications. Their expansion mechanism ensures that they provide a firm and secure hold inside concrete and masonry materials. This makes them ideal for use in securing structural elements, machinery, and other equipment that require a high degree of stability.

Corrosion Resistance

Many wedge anchors are made from materials that are resistant to corrosion, including stainless steel or galvanized steel. This makes them ideal for use in outdoor and industrial environments where they may be exposed to moisture, chemicals, or extreme weather conditions. Corrosion-resistant wedge anchors ensure the longevity of your installation without compromising on strength.

Easy and Fast Installation

Wedge anchors are relatively simple to install compared to other types of fasteners. The installation process generally involves drilling a hole into the concrete or masonry, inserting the anchor, and tightening the bolt to activate the expansion mechanism. This fast installation process reduces labor costs and downtime, making wedge anchors an efficient choice for various projects.

Vibration and Shock Resistance

The expansion mechanism in wedge anchor bolts ensures that the fastener stays securely in place, even when subjected to vibrations or dynamic loads. This makes them ideal for use in environments where equipment may experience significant movement, such as in machinery installations or structural applications that need to withstand wind or seismic forces.

Long-Lasting and Reliable

Due to their design and materials, wedge anchor bolts provide a permanent and reliable fastening solution. Once installed, they do not require maintenance or re-tightening, making them an ideal choice for long-term installations. The secure grip they provide ensures that your equipment or structure remains in place for years to come.

Wedge anchor bolts come in several different types, each designed to meet specific application needs. Below are the most common types of wedge anchors:

Standard Wedge Anchors

Standard wedge anchors are the most common type of wedge anchor. They consist of a bolt, a wedge, and a sleeve. These anchors are used in a wide variety of applications, from construction to industrial machinery installations. Standard wedge anchors are ideal for securing medium to heavy loads in concrete or masonry surfaces.

Best for: General-purpose fastening, securing equipment, and machinery

Advantages: High load-bearing capacity, simple installation

Disadvantages: Requires precise hole drilling

Hex Nut Wedge Anchors

Hex nut wedge anchors feature a hex nut on the top of the bolt, making them ideal for applications where the anchor needs to be installed with a wrench or spanner. These anchors are often used in industrial or commercial applications where precision and reliability are essential.

Best for: Industrial machinery, large equipment installations

Advantages: Strong, reliable hold, easy to tighten with a wrench

Disadvantages: Requires access to the top of the installation area

Double-Expansion Wedge Anchors

Double-expansion wedge anchors are designed with a double-expansion mechanism for added security and strength. When tightened, both ends of the wedge anchor expand, creating an even firmer grip inside the hole. These anchors are ideal for applications that require high load-bearing capacity and secure fastening.

Best for: Heavy-duty applications, large machinery, structural installations

Advantages: Double expansion mechanism for added security, high load capacity

Disadvantages: Requires precise installation

Stainless Steel Wedge Anchors

Stainless steel wedge anchors are designed for use in environments where corrosion resistance is critical. These anchors are made from stainless steel, which provides superior protection against rust and corrosion, making them ideal for marine, chemical, or outdoor applications.

Best for: Outdoor installations, marine applications, and exposure to harsh chemicals

Advantages: Corrosion-resistant, long-lasting

Disadvantages: Higher cost compared to standard steel anchors

Galvanized Wedge Anchors

Galvanized wedge anchors are coated with a layer of zinc to protect against corrosion. The galvanized coating ensures that these anchors remain durable and reliable, even in outdoor environments or areas with high humidity.

Best for: Outdoor installations, construction projects in damp environments

Advantages: Corrosion-resistant, affordable

Disadvantages: Galvanized coating can wear off over time in harsh conditions

Wedge anchor bolts are used in a wide variety of applications due to their strength, versatility, and ease of installation. Below are some common applications for wedge anchors:

Construction and Structural Fastening

Wedge anchors are commonly used in the construction industry to secure structural elements, such as beams, columns, and foundation elements, to concrete or masonry surfaces. These anchors ensure that critical components remain firmly in place, even under high-stress conditions.

Machinery and Equipment Installation

In industrial settings, wedge anchors are used to secure heavy machinery, equipment, and tools to concrete floors. They provide a strong, stable foundation for equipment that must remain in place during operation, ensuring the safety and reliability of machinery in manufacturing, assembly lines, and warehouses.

Outdoor and Marine Installations

Wedge anchors are ideal for outdoor applications due to their corrosion-resistant options, such as stainless steel or galvanized steel. They are used to secure outdoor structures like fences, light posts, and signage to concrete or stone surfaces. These anchors are also commonly used in marine environments to secure equipment and structures exposed to saltwater.

Electrical and Utility Installations

Wedge anchors are frequently used in the electrical and utility industries to secure power equipment, transformers, and poles to concrete foundations. They provide a solid and reliable fastening solution that ensures equipment stays in place, even during high-wind or seismic events.

Signage and Streetlight Installations

Wedge anchors are also commonly used to secure streetlights, traffic signs, billboards, and other outdoor signage. These fasteners ensure that the signs and lights stay securely in place, even when subjected to wind, rain, and other environmental factors.

Installing wedge anchor bolts is a straightforward process, but it is essential to follow proper procedures to ensure a secure installation. Below is a step-by-step guide for installing wedge anchor bolts:

Drill the Hole

The first step is to drill a hole into the concrete or masonry surface. The hole diameter and depth should match the specifications of the wedge anchor being used. Use a hammer drill and a carbide-tipped drill bit to create a clean, accurate hole.

Insert the Anchor

Once the hole is drilled, insert the wedge anchor bolt into the hole. Ensure that the bolt is aligned properly and that the threaded portion of the bolt is protruding from the surface.

Tighten the Bolt

Using a wrench or impact driver, tighten the nut on the anchor bolt. As the nut is tightened, the wedge-shaped component will expand, creating a firm hold inside the hole. Continue tightening until the anchor is secure.

Cangzhou Yangkang is a professional supplier in the photovoltaic and infrastructure fields, focusing on the R&D and production of Ground screws (helical ground anchors), Photovoltaic (PV) Mounting Systems, Bolts, Fence caps, Wire Mesh and other products.

About

Copyright © 2022 Cangzhou Yangkang Trading Co., Ltd

SitemapMain business area: Huanghua Cangzhou CHINA

This website uses cookies to ensure you get the best experience on our website.